Mechanical Metallurgy is the area of knowledge which deals with the behavior and response of metals to applied foeces.

This subject primarily concern to study the effect of external forces on metals. The forces may arise from the use of the metal as a member or part of a stucture or a machine. And hence, it becomes necessary to know about the materials limiting values which can be withstood without failure. In this section of metallurgy we will study about -

- Theories of strength of materials, elasticity, plasticity and mathematical representation of stress and strain.

- Fundamentals of mechanical behaviour of materials and atomistic concepts of the flow and fracture of metals

- Application of materials testing and different type of failure occuring in metals

- Improving a materials strength based on its application.

Assumption for Materials engineering :

(1) Should be Continuous, Homogeneous (same property in one direction at every point) and Isotropic (same property in every direction from a point )

(2) Should obey Hooke's law : stress and strain should be propertional within elastic limit.

(3) Should have uniform cross sectional area through out the length.

(4) Load is assumed as a Static Load.

(5) Weight of the material itself is neglected.

Elastic and Permanent Deformation :

When a solid is subjected to an external load, it undergoes a change in shape. When the load is released, and shape returns to its original shape prior to the application of the load then this is a Elastic deformation. However, the shape may not return to what it was prior to the application of the Load, under these circumstances we say that the material has deformed permanently.

Elastic deformation : When the dimension of a deformed body is recovered completely to its origininal dimension when load is removed is called elastic deformation. This behaviour is only observed upto the elastic limit i.e., where Hooke's law is applicable.

Plastic / Permanent deformation : If the elastic limit is exceeded, the body will experience a parmanent deformation, which is an unrecovered dimension left after removal of the load.

Difference between failure and fracture :

Failure : When the suject is not able to perform desirable or intended objective

Fracture : Separation of an specimen or material into two or more pieces under the action of applied / induced stress.

Load is define as any external force or a couple through with material is tested for its functionality.

Classification of Loads

|

Based on time

Based on load direction

Based on load distribution

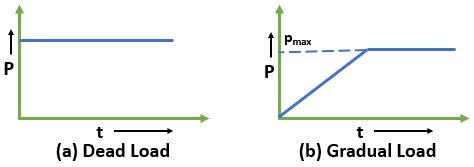

(1) Static Load : Load does not change with time

(a) Dead Load

(b) Gradual Load

(2) Dynamic Load :

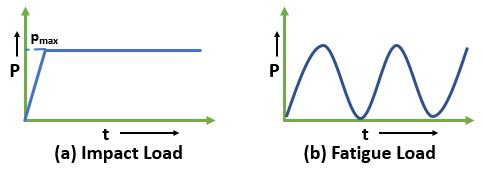

(2) Dynamic Load : Load changes with time

(a) Impact Load

(b) Fatigue Load

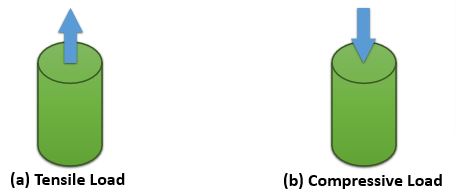

(1) Normal Load : The applied load is perpendicular to the plane of cross-section

(a)Tensile Load

(b)CompressiveLoad

(2) Shear Load :

(2) Shear Load : The applied load is parallel to the plane of cross-section

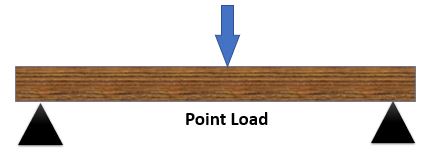

(1) Concentrated Load or point load : The applied load is concetrated at a point

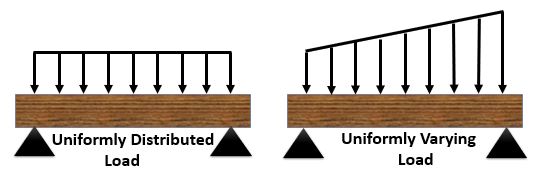

(2) Distributed Load :

(2) Distributed Load : The load applied across a length or area instead of at one point

(a)Uniformly Distributed Load

(b)Uniformly Varying Load

(c)Non-uniformly Distributed Load

Learn Metallurgy

Learn Metallurgy