Learn Metallurgy

Learn Metallurgymail@learnmetallurgy.com

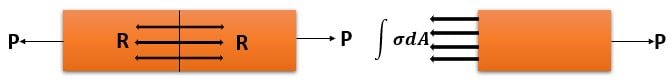

In above figure, left figure shows a prismatic bar applied with a load 'P', which develops a total internal resisting force (R) on cross-section, and figure on right shows the free body diagram of left fig. Then the Stess can be define as the magnitude or intensity of internal resisting force developed at a point in a member under given load.

\[ \sigma = \frac{dF}{dA} \] \[ \textrm{ On Integration : } \int{dR} = R = \sigma \int{dA} \] \[ \Rightarrow R = \sigma A \] \[ \boxed{ \sigma_{avg} = \frac{R}{A} = \frac{P}{A} } \] Stress Vs Pressure :| Stress | Pressure |

|---|---|

| stress magnitude can be different in different direction | Same in every direction |

| Stress can't be measured | Pressure gauges can be use to measure pressure |

| Acts normal or along to the applied load | Acts normal to the surface |

| Stress may be tensile, compressive and shear | Pressure is always compressive |

| Stress is a Second order tensor | Pressure is a scalar quantity |

Engineering stress : It is the ratio of applied load at any instant to average original cross-sectional area. Engineering Stress is denoted S or \( \sigma_{e} \).

\[ S = \sigma_{e} = \frac{P}{A_{0}} \] Where P is applied load and \( A_{0} \) is Avg. Cross-sectional area

True stress : It is the ratio of applied load at any instant to instantaneous cross-sectional area. True Stress is denoted as \( \sigma_{T} \).

\[ \sigma_{T} = \frac{P}{A} \]

Where P is applied load and \( A \) is instantaneous Cross-sectional area

Units of Stress : Pa ( \( \frac{N}{m^2} \) ) , MPa ( \( 10^6 \frac{N}{m^2} \) = 1MPa ) , \( \frac{kgf}{cm^2} ( 1kgf = 9.81N \Rightarrow 1\frac{kgf}{cm^2} = 0.1MPa ) \)

Relation between True stress and Engineering stress:

\[ \sigma_{T} = \sigma_{e}( 1 + e ) \]

\( e \) = Engg. Strain

\( \sigma_{e} \) = Engg. Stress

\( \sigma_{T} \) = True Stress

Engineering strain : It is the ratio of change in dimension to original dimension om application of load. Engineering Strain is denoted e.

\[ e = \frac{\Delta L}{L_{0}} \]

Where \( \delta L \) is change in dimesion and \( L_{0} \) is original length

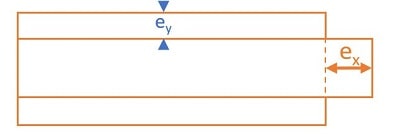

Longitudinal Strain \( (e_{x}) \) : It is the normal strain in the direction of applied load

Longitudinal Strain \( (e_{x}) \) : It is the normal strain in the direction of applied load

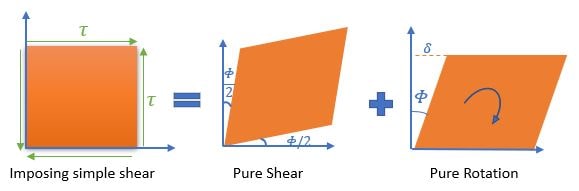

Shear strain is defined as the change in initial right angle between two lines elements which are parallel to x and y axes. The above figure shows the simple shear strain is a combination of pure shear and rotation. Shear strain can be calculated as \( \gamma = \phi^\textrm{shear angle} \)

\[ tan\phi^\textrm{shear angle} = \frac{\delta}{L} \]

\( \textrm{As }\phi \textrm{ is so small } \Rightarrow \phi = \frac{\delta}{L} \)

\[\boxed{ \gamma = \frac{\delta}{L} } \]

| Material | Independent Elastic Constant |

|---|---|

| Isotropic | 2 |

| Orthotropic | 9 |

| Anisotropic | 21 |

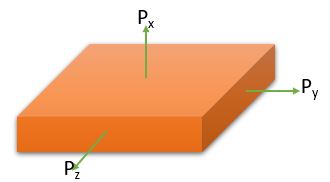

As mentioned earlier , Every longitudinal strain is associated with 2 lateral strain. For above case the longitudinal strain in x-direction \( \frac{\sigma_{x}}{E}\) is associated with 2 lateral strain \( -\frac{\mu \sigma_{x}}{E} \). So for all direction :

As mentioned earlier , Every longitudinal strain is associated with 2 lateral strain. For above case the longitudinal strain in x-direction \( \frac{\sigma_{x}}{E}\) is associated with 2 lateral strain \( -\frac{\mu \sigma_{x}}{E} \). So for all direction :

| \( \frac{Strain \rightarrow}{Load \downarrow} \) | X-Direction | Y-Direction | Z-Direction |

|---|---|---|---|

| Px | \( \frac{\sigma_{x}}{E}\) | \( -\frac{\mu \sigma_{x}}{E} \) | \( -\frac{\mu \sigma_{x}}{E} \) |

| Py | \( -\frac{\mu \sigma_{y}}{E} \) | \( \frac{\sigma_{y}}{E}\) | \( -\frac{\mu \sigma_{y}}{E} \) |

| Pz | \( -\frac{\mu \sigma_{z}}{E} \) | \( -\frac{\mu \sigma_{z}}{E} \) | \( \frac{\sigma_{z}}{E}\) |